2 Types of Welding Machines You Need to Know in the Industrial World

09 November 2023

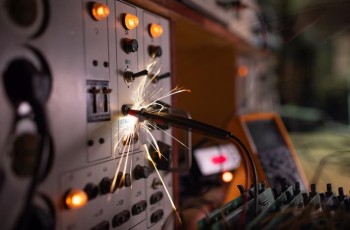

Sobat Honda, for you in the industrial world with a business or enterprise that requires welding machines, it's essential to comprehend the various available welding machines. Welding machines are vital devices in industry, construction, and manufacturing.

In an industrial context, welding machines combine materials such as metals, plastics, or other substances to create robust and durable structures. Producing solid and high-quality welds is critical across various sectors, including vehicle manufacturing, building construction, industrial equipment repairs, and more.

As a result, having an in-depth understanding of the various types of welding machines and how they operate is critical to achieving high-quality welding results, enhancing productivity, and ensuring workplace safety.

This article will provide an in-depth discussion of the different types of welding machines that Sobat Honda can consider for various industrial needs. Let's delve into the comprehensive description below.

Introduction to Welding Machines

Welding machines are tools used to fuse two materials by melting them and then cooling them to form a strong joint. This process is known as welding, and welding machines are the instruments used.

Welding is integral to various industries, including construction, automotive, manufacturing, and many others. Sobat Honda can efficiently and effectively perform high-quality welding by utilizing a suitable welding machine.

This welding process is employed to join various exact materials, creating solid joints resistant to pressure, heat, and environmental stress, which may be encountered in multiple industrial applications.

Read Also: What Causes The Unstable Voltage Of Generator?

Types of Welding Machines

Several types of welding machines are available for Sobat Honda’s specific needs. Each class has unique characteristics and different applications. Here are some types of welding machines that Sobat Honda should be aware of:

1. Acetylene Welding Machine

Acetylene welding machines, more commonly known as oxyacetylene welding machines, use calcium carbide and oxygen to produce the high heat required for metal fusion. These welding machines are typically used for cutting and welding metals.

This welding process is well-suited for thick and strong metals like steel. The main advantage of acetylene welding machines is their portability, as they can be used in locations without electricity, making them ideal for outdoor projects.

Acetylene welding machines play a crucial role in the industry, especially in cutting large and complex metal structures. Their ability to generate high heat and operate without electrical power makes them versatile and practical.

2. Electric Welding Machine

Electric welding machines are the most commonly used type of welding machine. They work by utilizing electric current to melt metal and form welds. Electric welding machines are highly versatile and can be used for various welding types, including thin and thick metals. These machines are also suitable for welding in different positions, such as flat, vertical, and overhead.

For electric welding machines, there are three essential subtypes that Sobat Honda should be aware of for field use. Let's take a look at them below.

a. Alternating Current (AC) Welding Machine

AC welding machines produce an electric current that periodically changes direction. This type of welding machine is commonly used for welding conductive metals. The welding process results in a stable electric arc, making it suitable for welding steel and stainless steel.

Sobat Honda, if you are working in industries dependent on welding metals, understanding AC welding machines is essential. The machine's ability to create stable and high-quality welds on conductive metals can help ensure the safety and reliability of structures.

b. Direct Current (DC) Welding Machine

DC welding machines generate an electric current that flows in one direction. This welding machine is suitable for welding less conductive metals like aluminum and magnesium. DC welding machines are often used for welding thick metal stacks or in challenging positions.

The process of converting alternating current into direct current in welding machines varies depending on the type and technology used in the machine. Generally, welding machines with a DC power source rely on an electric dynamo or rectifier as a rectifying device to convert AC into DC.

Read Also: Get To Know The Differences Between DC And AC Generators

c. Dual-Purpose or AC-DC Welding Machine

Dual-purpose or AC-DC welding machines combine both AC and DC welding capabilities. Sobat Honda can use these machines for various types of metals and different welding applications. Dual-purpose welding machines are highly flexible and commonly used in the automotive and construction industries.

The alternating current output signal is obtained from the secondary winding terminal of the transformer through a current regulator. Similarly, direct current is taken from the output of the current rectifying device. Alternating current or direct current settings can be adjusted easily, by simply turning the current controller on the welding machine

The advantage of AC-DC welding machines is their higher flexibility, as they can perform welding tasks similar to both DC and AC welding machines. This type of welding machine is often chosen for workshops that handle various tasks, and doesn’t need to switch devices for diverse welding needs Sobat Honda.

In the industrial world, selecting the correct type of welding machine can significantly impact the quality and success of a project. Acetylene welding machines are ideal for welding thick metals, while electric welding machines provide greater flexibility for various welding tasks. Within electric welding machines, there are alternating current (AC), direct current (DC), and dual-purpose devices to choose from according to specific needs.

Therefore, for those of you engaged in the industrial world, it's crucial to understand these various types of welding machines to make informed decisions for Sobat Honda’s ongoing projects.

When selecting the most suitable welding machine, consider the type of material Sobat Honda will be welding, the welding positions required, and the workplace environment. If Sobat Honda understands these welding machine types well, Sobat Honda can optimize your welding results and enhance work efficiency.

During the use of electric welding machines, it's essential to have a backup power source, such as a generator, to ensure Sobat Honda’s work isn't interrupted when the main power supply fails.

Read Also: Tips For Choosing Generator Based On Electricity Needs

Sobat Honda doesn't need to worry about finding a generator because Honda Power Products offers a variety of generator types equipped with advanced technology. They provide peace of mind and can be used continuously for 7-8 hours.

Discover the best and most reliable Honda Power generator according to Sobat Honda’s needs only at Honda Power Products. Check prices and specifications now.

Honda Power Products Indonesia

Honda Power Products menyediakan mesin serbaguna, generator, pemotong rumput, pemotong sikat, pompa air, dan mesin tempel.